-

- Aluminum Melting Furnace The aluminum and aluminum alloy melting furnace utilizes aluminum ingots, recovery materials, recycled materials, and other raw inputs to produce a variety of aluminum products, including aluminum rods (1 series, 6 series, 8 series), aluminum ingots, and aluminum bars. This furnace ensures high efficiency and quality in aluminum production.

-

- Aluminum Rod Continuous Casting and Rolling Line This production line is mainly used for producing high-conductivity electrical aluminum rods with diameters of 9.5mm, 12.5mm, and 15mm, meeting European and American standards for EC1350 series, 3#, 5# (5005, 5154), 6# (6101/6201), and 8# (8176, 8030) series.

-

- Aluminum Rod Breakdown Machine The aluminum rod breakdown machine with individual motors is used to produce aluminum wires sized ⌀1.6-4.5mm from aluminum rods of ⌀9.5mm, or wires sized ⌀2.1-4.5mm from aluminum alloy rods of ⌀9.5mm.

-

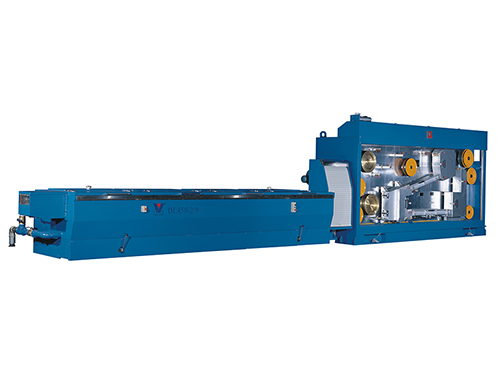

- Copper Rod Breakdown Machine The copper rod breakdown machine with individual motor is designed for drawing copper wires from ⌀8mm low-oxygen or oxygen-free copper rods to ⌀1.2-4.5mm. This machine also performs annealing during the drawing process, producing high-quality copper wires for electrical purposes.

-

- Multiwire Drawing Machine Designed for efficiency and precision, the multiwire drawing machine with annealer processes multiple strands of copper wire simultaneously. It can handle 8-24 strands of ⌀1.6-3.5mm low-oxygen or oxygen-free copper wires, as well as electroplated tin copper wires, transforming them into 8-24 strands of ⌀0.15-1.05mm copper wires while performing annealing. The finished wires are neatly coiled into spools, ready for use.

-

- Continuous Rotary Extrusion Machine The continuous rotary extrusion machine is designed for processing copper and aluminum rods into a variety of products, including solid, hollow, shaped, and multi-porous flat sections. This machine excels in producing items with good elongation properties, uniform dimensions, and low resistivity. It can create profiles that traditional drawing machines cannot achieve, such as fan-shaped, H-shaped, S-shaped, and L-shaped products.