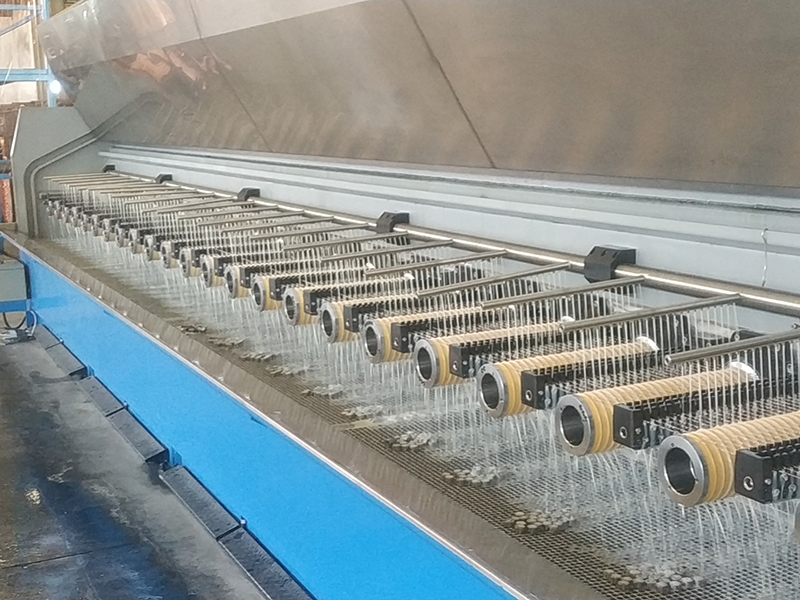

Multiwire Drawing Machine with Annealer

Wire drawing machine for copper wires

Designed for efficiency and precision, the multiwire drawing machine with annealer processes multiple strands of copper wire simultaneously. It can handle 8-24 strands of ⌀1.6-3.5mm low-oxygen or oxygen-free copper wires, as well as electroplated tin copper wires, transforming them into 8-24 strands of ⌀0.15-1.05mm copper wires while performing annealing. The finished wires are neatly coiled into spools, ready for use.

Features

- Combines wire drawing and annealing processes, ensuring high production efficiency, stable resistivity, and consistent elongation.

- Ensures stable product quality and uniform dimensions, with high production efficiency and low labor intensity for workers.

- Available with gear drive or individual motor drive systems. Choose from 8-head, 14-head, 16-head, 20-head, or 24-head configurations based on your production needs.

- Gear drive is ideal for continuous drawing and annealing of ⌀0.2-1.05mm wires, offering excellent cost-performance ratio.

- The individual motor drive system produces a full range of high-quality products, with stable output, high efficiency, and low noise.

- Each drawing drum is independently driven, allowing precise control of compression ratios for better mold matching and adaptability to different wire grades.

- Optional take-up systems include single or multiple spool configurations.

- Utilizes an MMI+PLC control system for synchronized control of the entire production line. Real-time monitoring and easy adjustment of process parameters via the touch screen ensure efficient and user-friendly operation.

- Offers a range of auxiliary equipment, including threading machines, cold welding machines, heat exchangers, and oil filtration systems, providing a complete turnkey solution for seamless operation.

Specifications

| Model | Inlet wire rod diameter (mm) | Outlet wire diameter (mm) | Max. drawing pass | Max. speed (m/min) | Installed capacity (kVA) | Bobbin size (mm) |

HTBT21-16 | 16*⌀1.8 8*⌀2.6 | 16*(⌀0.18-⌀0.4) 8*(⌀0.4-⌀0.52) | 21 | 1800 | 330 | 2*PND630 |

HTBT25-16 | 16*⌀1.8 8*⌀2.6 | 16*(⌀0.15-⌀0.4) 8*(⌀0.4-⌀0.52) | 25 | 1800 | 330 | 2*PND630 |

HTBT16-14 | 14*⌀1.8 7*⌀2.6 | 14*(⌀0.28-⌀0.52) 7*(⌀0.4-⌀1.05) | 16 | 1800 | 530 | 2*PND630 |

HTBT20-14 | 14*⌀1.8 7*⌀2.6 | 14*(⌀0.20-⌀0.52) 7*(⌀0.4-⌀1.05) | 20 | 1800 | 530 | 2*PND630 |

HTBT21-8 | 8*⌀1.8 | 8*(⌀0.15- ⌀0.52) | 21 | 1800 | 240 | 1*PND630 |

HTBT17-8 | 8*⌀1.8 | 8*(⌀0.2-⌀0.52) | 17 | 1800 | 240 | 1*PND630 |

HTBT16-8 | 8*⌀1.8 7*⌀2.6 | 8*(⌀0.28-⌀0.85) 7*(⌀0.4-⌀1.05) | 16 | 1800 | 510 | 1*PND630 |

Related Machines

Get in Touch