Rigid Cage Stranding Machine, KJ630

Rigid stranding line for manufacturing copper and aluminum conductors with large cross sections

Rigid Cage Stranding Machine: Efficient Stranding for Large Cross-Section Conductors

Introducing our rigid cage stranding machine, the KJ630, designed for the efficient manufacturing of copper and aluminum conductors with large cross-sections. This advanced stranding machine eliminates the need for backtwist during the stranding process, ensuring high-quality results. Additionally, it can handle both round and sector-shaped conductors, as well as pre-twisted compaction operations for segmented conductor.

Features

- Robust frame structure for enhanced rigidity and high-speed operation

- Dual active traction and support devices for increased strength and pulling force

- Natural wire distribution system to prevent conductor abrasion during stranding

- Automatic wire breakage detection and immediate machine stoppage for enhanced safety

- PLC control for smooth operation, reliable performance, and high automation

Specifications

| No. of Drums in cage | 6, 12, 18, 24, 30, 36 |

| Dia. of single wire | copper: 1.5-4.5mm |

| aluminium: 1.8-5.0mm | |

| aluminium alloy: 1.5-4.5mm | |

| Cage rotating speed | 6-bobbin: 220 r/min 12-bobbin: 200 r/min |

| 18 bobbin: 180 r/min 24 bobbin: 160 r/min | |

| 30 bobbin:120r/min | |

| 36 bobbin: 100 r/min | |

| Stranding pitch | 6 bobbin: 37-500 mm 12 bobbin: 44-590 mm |

| 18 bobbin: 52-694 mm | |

| 24 bobbin: 61-819 mm | |

| 30 bobbin:72-965mm | |

| 36 bobbin: 85-1300 mm | |

| Line speed | 6.9~53m/min |

| Sizes of bobbin in cage | PND 630 |

| Centre height | 1100mm |

| Capstan unit | Ø2000 (2500、3150) Dual pulling Capstan |

Details

Pay-Off

- Optional with mechanical tension control or tensioning with magnetic particle brakes, ensuring stable, adjustable tension control

- Automatic machine stoppage in case of wire breakage

Wire Guide

Stranding Cage

Take-Up

- Motorized wire clamping with mechanical and electrical protection mechanisms

- Easy loading and unloading of wire bobbins

- Synchronization with the main machine for continuous tension during operation and delayed stoppage after machine shutdown

Double Wheel Capstan

- Dual-driven wheels with natural wire distribution to prevent conductor damage

- Pneumatic pressure system to prevent cable slippage during startup

- Excellent synchronization and pulling force

- Safety overload protection with pin coupling

Meter Counter

- Non-contact electronic meter counter for accurate and reliable measurements

- Mechanical meter counter included

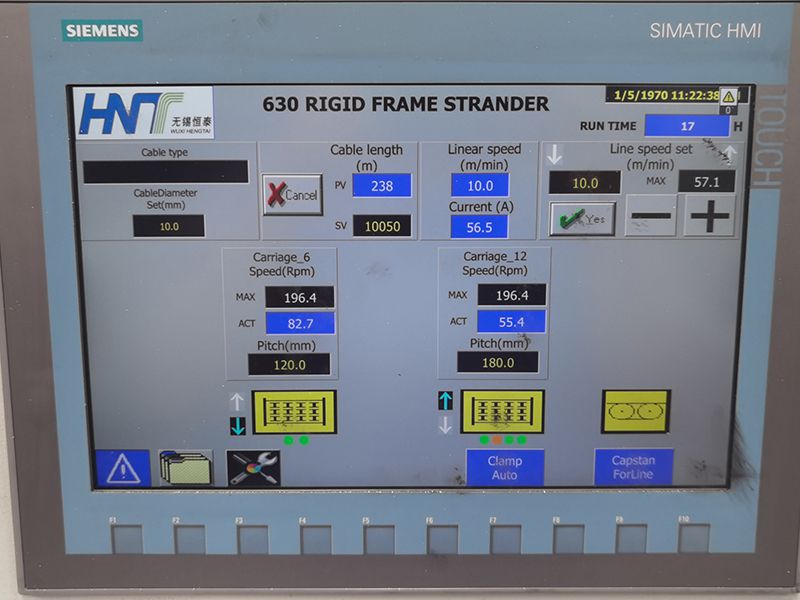

Control System

- Siemens PLC control for smooth operation and reliable performance

- All technical parameters adjustable via the touchscreen interface, with the ability to store production process parameters

Related Machines

Get in Touch