Flat Elevator Cable Extrusion Line

Cable extruder line for elevator traveling cable insulation and sheathing

Our flat elevator cable extrusion line is designed to meet the specific requirements of elevator traveling cable insulation and sheathing.

Features

- Insulation Extrusion Material: TPU (Thermoplastic Polyurethane)

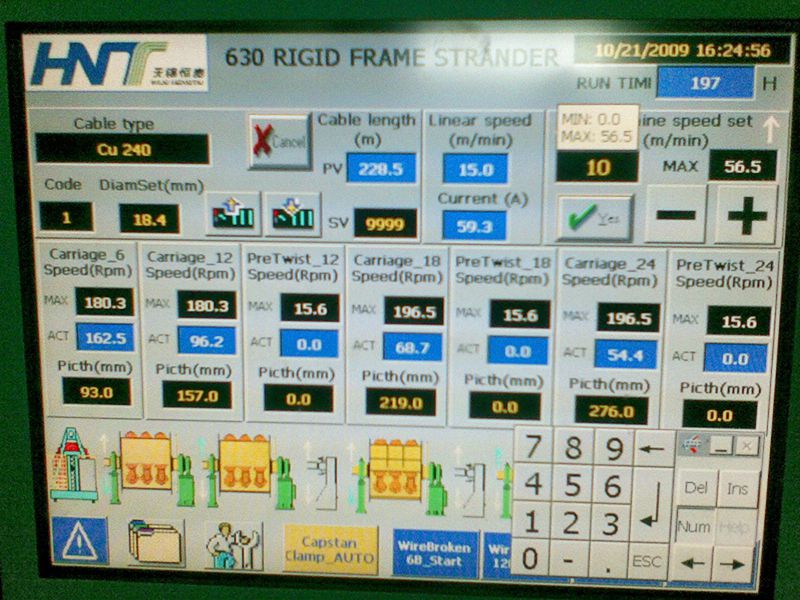

- Control System: Touchscreen Interface and PLC (Programmable Logic Controller)

- Line Speed (Traction Caterpillar): Maximum 30m/min

- Temperature Control: Our cable extrusion machinery employs Japanese RKC modules for temperature control, communicating with the PLC. The system includes a dedicated temperature control interface with an ambient temperature reference.

- Siemens S7-1500 PLC Control: The entire cable extrusion machinery is controlled by the Siemens S7-1500 PLC programmable controller, operated through an industrial panel display and interface.

- Profibus Communication Bus: The implementation of a Profibus communication bus enables seamless human-machine communication and control. This system controls the entire production line based on screw speed, involving a diameter gauge for precise control. The PLC adjusts the traction speed based on external diameter fluctuations, ensuring consistent cable outer diameter.

Details

Pay-Off

- Multi-Head Active Pay-Off

- Tension Range: 10N to 200N with a 3% error

- Tension Control Method: Dancer Roll System with proportional pressure

Take-Up

- Motorized wire clamping with mechanical and electrical protection mechanisms

- Easy loading and unloading of wire bobbins

- Synchronization with the main machine for continuous tension during operation and delayed stoppage after machine shutdown

Control System

- The entire cable extrusion machinery is controlled by the Siemens S7-1500 PLC programmable controller, operated through an industrial panel display and interface.

- Parameter Storage and Modification: Different production process control parameters are stored in the computer system and can be easily accessed and modified through the touchscreen display. The use of an industrial panel interface facilitates convenient parameter adjustment. The production line can be centrally controlled, enabling single or coordinated adjustments.

- Displayed Info: The display provides information such as outer diameter, barrel pressure, pressure limit alarms, extruder and traction motor load limits, emergency stop button alarms, extruder material level empty alarms, production speed, screw speed, current, outer diameter, and extrusion head pressure.

Related Machines

Get in Touch