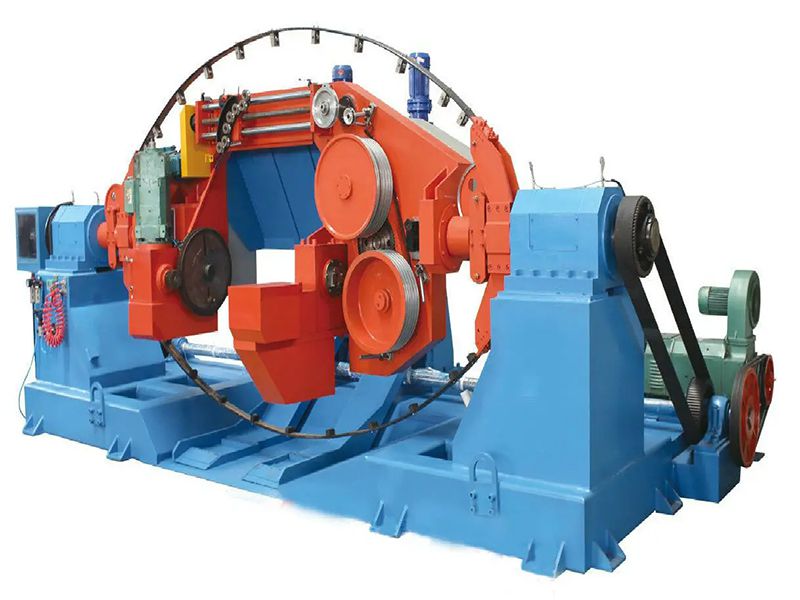

Double Twist Bunching Machine, JLT Series

Double twist buncher for manufacturing strands and ropes made of copper and aluminum wires

Double Twist Bunching Machine: Efficient Stranding for Long and Large Cross-Section Copper and Aluminum Strands

We offer the double twist bunching machine, designed for the efficient stranding of copper and aluminum strands and ropes. This bunching machine is suitable for manufacturing long-length, large cross-section aluminum/aluminum alloy wires, bare copper wires, steel core aluminum conductors, sector-shaped conductors, and cross-linked compressed cable cores.

Features

- Carbon fiber composite materials for lightweight and sturdy construction, enhancing machine performance and lifespan

- Closed safety design with noise isolation, improving work efficiency and operator comfort

- Stepless PLC control technology for digital setting and automatic operation. Parameter adjustments and settings can be easily performed through the touchscreen interface.

- Independent motor-controlled winding tension with a precise feedback control system

- Four equally divided wire bobbins mounted around the stranding cage, ensuring high rigidity, overall performance, and smooth operation

- Optional features include pre-stranding devices, mechanical tension pay-offs, wire tension control devices, power supply wire feeders, and more.

Specifications

| Model | JLT 1250 | JLT 1600 | JLT 1800 | JLT 2000 | JLT 2240 | JLT 2500 |

| Dia. of wire (mm) | 1.0-3.0 | 1.5-4.8 | 1.5-4.8 | 1.5-4.8 | 1.5-4.8 | 1.5-4.8 |

| Section of strand (mm) | 3.5-70 | 16-240 | 16-240 | 16-240 | 16-240 | 16-240 |

| Section of stranding (1+6) (mm) | 3.5-50 | 16-50 | 16-50 | 16-50 | 16-50 | 16-50 |

| Section of compaction (cu) (mm) | 3.5-50 | 16-150 | 16-185 | 16-240 | 16-300 | 16-300 |

| Section of compaction (AI) (mm) | 3.5-70 | 16-240 | 16-240 | 16-300 | 16-400 | 16-400 |

| Max finished wire diameter (mm) | 10 | 25 | 35 | 35 | 35 | 35 |

| Max compaction coefficient | 85-90% | 85-90% | 85-90% | 85-90% | 85-90% | 85-90% |

| Max line speed (m/min) | 70-150 | 170-200 | 170-200 | 170-200 | 170-200 | 170-200 |

| Max strand outer diameter (mm) | 15 | 25 | 35 | 35 | 35 | 35 |

| Max rotation speed (rpm) | 800 | 600 | 350 | 350 | 300 | 300 |

| Stranding pitch (mm) | 40-350 | 40-350 | 50-600 | 60-600 | 60-600 | 60-600 |

Related Machines

Get in Touch