Crosslinked Insulation Extrusion Line

Extruder line for production of silane cross-linked cable material in a one-step process

The one-step silicohydride crosslink insulation extrusion line is designed for the insulation extrusion of cooper and aluminum conductors. Our crosslink insulation extrusion line is suitable for power cables ranging from 1kV to 10kV, overhead conductors, plastic cables and etc. Applicable materials include PVC, PE and XLPE.

Our crosslinked insulation extrusion lines boast high productivity, enabling continuous production and significantly improving efficiency.

Specifications

| Voltage Range | 1 kV for cross-linked cables 1 kV for overhead conductors 10 kV for cross-linked cables 10 kV for overhead conductors |

| Conductor Material | aluminum and copper |

| Aluminum Conductor | complying with IEC 228 standards |

| Copper Conductor | complying with IEC 228 standards |

| free from dust impurities, oil, and bending | |

| Conductor Shapes | round, sector, stranded, solid |

| Conductor Cross-section | 10 - 630 mm², copper 10 - 630 mm², aluminum |

| Conductor Diameter | 4,0 - 40,0 mm |

| Cable Outer Diameter | 9,5 - 42,0mm |

| Maximum Cable Weight | 70 kg/m |

| Insulation Thickness | Internal Shielding: 0.4- 0.8mm Insulation: 0.8-3.5 mm |

| Maximum Production Line Speed | 120 m/min. |

| Cable Path Height | 1.000 mm |

| Extruder Feeding | granular cable materials |

| Internal Shielding and Colored Jacket Extruder 65/25D | PE: 120 kg/h, Max. |

| Insulation Extruder 120/30D | PE: 480 kg/h, Max. |

| Medium Voltage Cables | |

| Internal Shielding | semi-conductive PE (e.g., Borealis) or SIOPLAS (AEI) |

| Insulation | PE (e.g., 2100TN00, 218W, 18D) Liquid Silane (e.g., SILIX, SILMIX316, 301) Carbon Black Masterbatch (SILIX-C401) |

| Low Voltage Cables | |

| Insulation | PE (e.g., 2100TN00, 218W, 18D) Liquid Silane (e.g., SILIX, SILMIX316) Carbon Black Masterbatch (SILIX-C401) |

| Colored Jacket | PE, PVC, or SIOPLAS (AEI), or other materials |

Details

Pintle Type Pay-Off

- Motor-controlled for lifting, opening, and movement, featuring limit protection

- Passive pay-off with mechanical tension control.

Take-Up

- Motorized wire clamping with mechanical and electrical protection mechanisms

- Easy loading and unloading of wire bobbins

- Synchronization with the main machine for continuous tension during operation and delayed stoppage after machine shutdown

Caterpillar Haul Off Unit

- Pneumatic clamping and automatic tensioning of the traction belt ensure low noise and high power output.

- Synchronization of traction speed with extruder speed ensures reliable and stable operation.

- The twin tracks feature a reinforced mesh layer, driven by an AC motor via a spiral bevel gear system with four-speed gearbox.

Meter Counter

- Non-contact electronic meter counter for accurate and reliable measurements

- Mechanical meter counter included

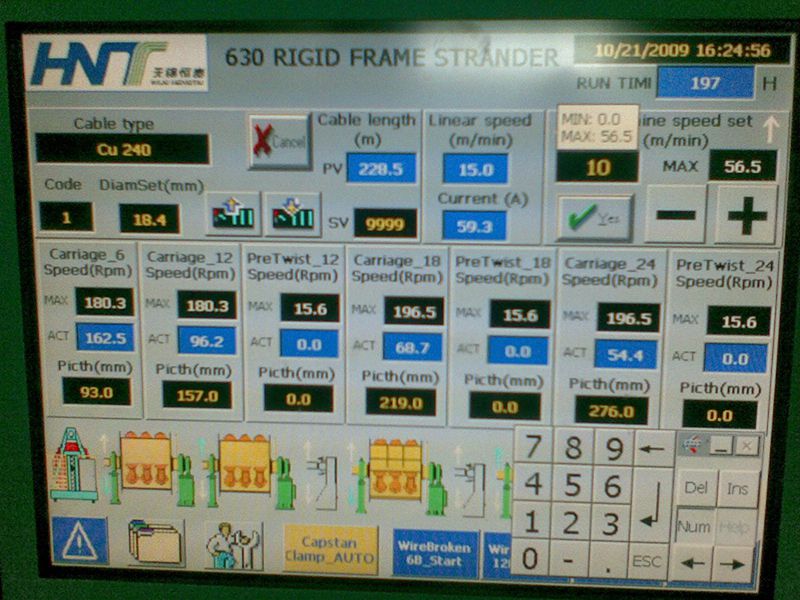

Control System

- Siemens PLC control for smooth operation and reliable performance

- All technical parameters adjustable via the touchscreen interface, with the ability to store production process parameters

Related Machines

Get in Touch