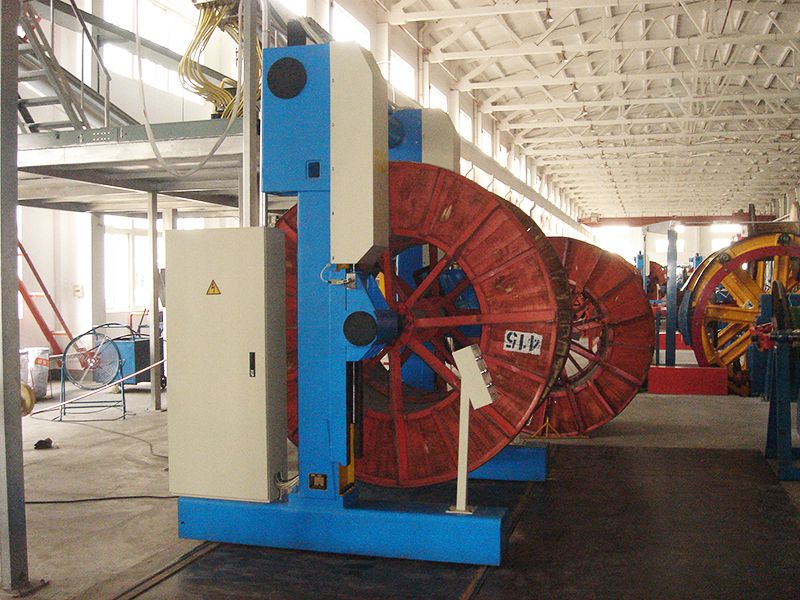

Power Cable Jacket Extrusion Line

200mm & 120mm twin-screw extruder line for cable sheathing

Enhance Your Cable Sheathing Process with Our Power Cable Jacket Extrusion Line

Our power cable jacket extrusion line is specifically designed for high-voltage cable sheathing and extrusion requirements. Our 200mm and 120mm twin-screw extruder line delivers exceptional performance, ensuring precise and efficient cable sheathing, applicable for PVC, PE, LDZH, LDLH, semiconductor PVC, semiconductor PE, and more.

Features

- Reduction Gearbox: Our extruder line incorporates precision-ground gears and a specialized reduction gearbox, ensuring smooth and reliable extrusion.

- High-Quality Materials: The main barrel and screw are made of 38GrMoA steel, treated with nitrogen for high hardness, wear resistance, and corrosion resistance.

- Cooling System: The barrel is cooled using a high-pressure centrifugal fan, ensuring optimal cooling during the extrusion process.

- Aluminum Heating Elements: Our extruder line features efficient cast-aluminum heating elements, monitored by precise temperature control instruments for easy adjustments.

- Sleek Design and Stable Transmission: Our extruder line is not only aesthetically pleasing but also features a well-designed structure for stable and reliable transmission.

Specifications

| Model | Ø 200 + Ø 120 |

| Screw diameter | Ø 200 mm + Ø 120 mm |

| Extrusion amount | 800 kg/h |

| Viable conductor shape | circular, sector, stranded, solid |

| Applicable material | PVC, PE, LDZH, LDLH, semi-conducting PVC, semi-conducting PE |

| Control mode | PLC |

| Max line speed | 80 m/min |

| Wire diameter control precision | ± 0.02 mm |

Details

Pay-Off

- Pneumatic mechanical tension control for smooth payout

- Proximity switch-based metering and wire break detection

Caterpillar Haul Off Unit

- Pneumatic clamping and automatic tensioning of the traction belt ensure low noise and high output efficiency.

- Synchronization of traction speed with extruder speed ensures reliable and stable operation.

- The twin tracks are driven by a DC motor via a spiral bevel gear system, ensuring excellent control and performance.

- The pneumatic clamping and release system offers sensitivity and reliability, featuring a pressure adjustment display instrument.

Take-Up

- Motorized wire clamping with mechanical and electrical protection mechanisms

- Easy loading and unloading of wire bobbins

- Synchronization with the main machine for continuous tension during operation and delayed stoppage after machine shutdown

Related Machines

Get in Touch