High Performance Plastic Extrusion Line, GJS Series

Screw extruder line for cable insulation and sheathing

At S&A, we take pride in offering the high-performance plastic extrusion line specifically designed for cable insulation and sheathing, covering LV to EHV power cable.

| Screw Diameter | L/D | Motor Power | Extrude Capacity (PVC) | Extrude Capacity (PE) |

| 30 mm | 25:1 | 5.5 kW | 25 kg | 15 kg |

| 45 mm | 25:1 | 15 kW | 80 kg | 45 kg |

| 65 mm | 26:1 | 30 kW | 160 kg | 90 kg |

| 80 mm | 26:1 | 75 kW | 260 kg | 165 kg |

| 90 mm | 26:1 | 90 kW | 360 kg | 210 kg |

| 120 mm | 26:1 | 132 kW | 620 kg | 380 kg |

| 150 mm | 25:1 | 200 kW | 900 kg | 550 kg |

| 200 mm | 25:1 | 280 kW (315 kW) | 1300 kg | 750 kg |

- Increased Extrusion Output: The plastic extrusion line outperforms conventional extrusion lines, providing a 50% higher extrusion volume and increased line speed.

- Unique Output Flow Design: Our plastic extrusion line incorporates a specially designed output flow channel, ensuring high-quality extrusion with an arc-shaped screw design.

- Screw Groove Structure: The innovative screw groove design significantly enhances extrusion quality compared to other screw designs.

- Efficient Plasticization: Our plastic extrusion line prevents plastic overheating and decomposition by enhancing shear while ensuring superior plasticization and homogenization for high-speed extrusion.

- Accurate Temperature Control: We utilize a high-precision temperature control system, employing the renowned RKC system from Japan.

- Wide Range of Extrusion Materials: The plastic extrusion line is compatible with various materials such as PP, PE, PVC, LSF-HFFR, XLPE, TPU, FEP, and ETFE.

- Advanced Air Control System: The control system combines an industrial computer and Siemens S7 series control, enabling synchronized control and standalone operation.

- User-Friendly Control Parameters: Our plastic extrusion line allows easy modification of control parameters, storing different production process control parameters in the computer for convenient centralized control and individual adjustments.

- Comprehensive Control System: Our control system fulfills production, monitoring, and data management tasks, offering process monitoring, alarm systems, process menu systems, historical data records, alarm logs, reports, system management, and printing capabilities.

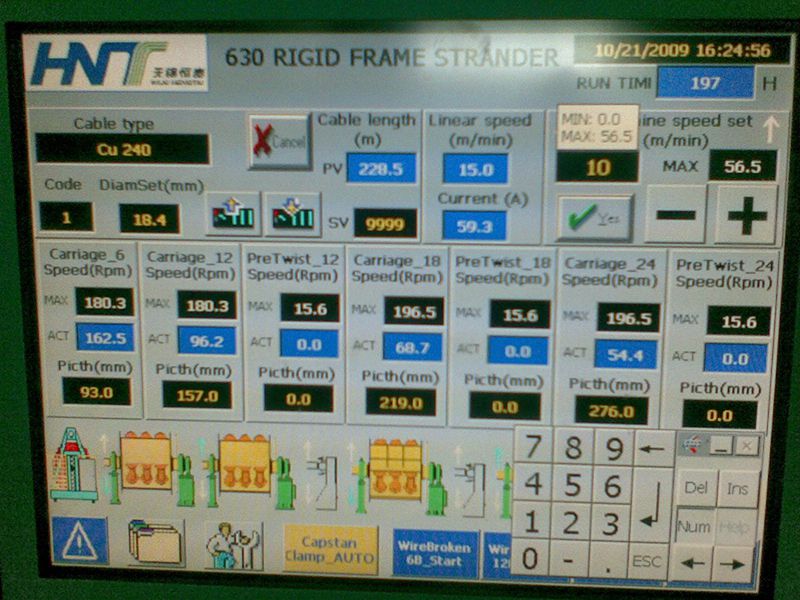

- Human-Machine Interface: The production operations are controlled through a user-friendly industrial computer interface, displaying parameters such as extrusion outer diameter, barrel pressure, line speed, screw speed, current, and head pressure in real-time and historical data curves.

Special Screw Design

Compared with normal power cable extrusion series, our extrusion line has 50% higher extrusion output due to the special screw design by HNT. The screw for our plastic extrusion line has special output flow paths designed for molten plastic to guarantee high quality of extrusion. The screw has an arc spiral structure, which provides much higher extrusion quality compared with other type of screw structures. Hotting-tube technology is adopted in the screw design, which strengthens cutting and also avoids plastic decomposition by overheating. Accordingly, the melting process is guaranteed to be even and the extrusion process can reach higher speed.

Accurate Temperature Control System

The barrel of the extrusion line adopts two main cooling systems. The inner water-cooling system and wind-cooling system with precisely-cut cooper wing-pieces are both mounted to ensure perfect heat balance during the extrusion process, which allow precise temperature control of the barrel.

Excellent Electric Control System

The whole plastic extrusion line is controlled by IPC (Industrial Personal Computer) and Siemens S1-300 PLC. All equipment within the GJS extrusion line can be operated simultaneously with synchronized linkage, but can also be controlled solely. Different control parameter of extrusion process can be stored in the computer and displayed together on the screen. Control parameters of the human-computer interface can be easily set to realize centralized control of the whole line.

Pay-Off

- Pneumatic mechanical tension control for smooth payout

- Proximity switch-based metering and wire break detection

Take-Up

- Motorized wire clamping with mechanical and electrical protection mechanisms

- Easy loading and unloading of wire bobbins

- Synchronization with the main machine for continuous tension during operation and delayed stoppage after machine shutdown

Double Wheel Capstan

- Dual-driven wheels with natural wire distribution to prevent conductor damage

- Pneumatic pressure system to prevent cable slippage during startup

- Excellent synchronization and pulling force

- Safety overload protection with pin coupling

Meter Counter

- Non-contact electronic meter counter for accurate and reliable measurements

- Mechanical meter counter included

Control System

- Siemens PLC control for smooth operation and reliable performance

- All technical parameters adjustable via the touchscreen interface, with the ability to store production process parameters